Phase 2: Environmental Upgrade, Comfortable Office - New Company Office Environment and Factory Workshop Preview (Part 2)

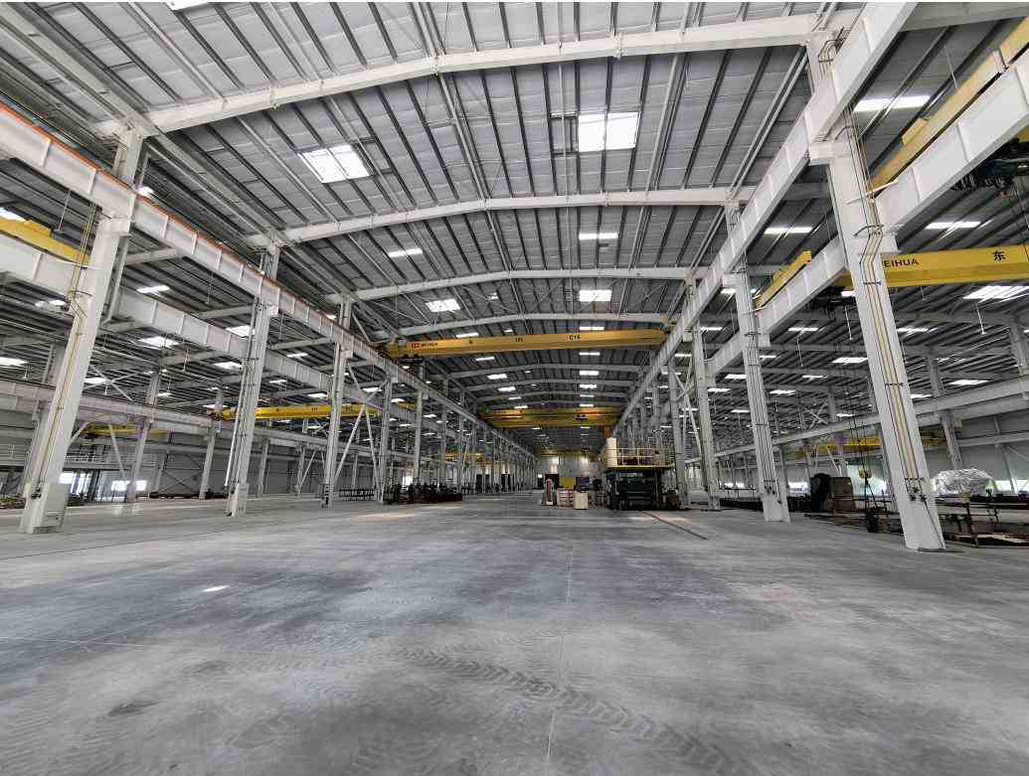

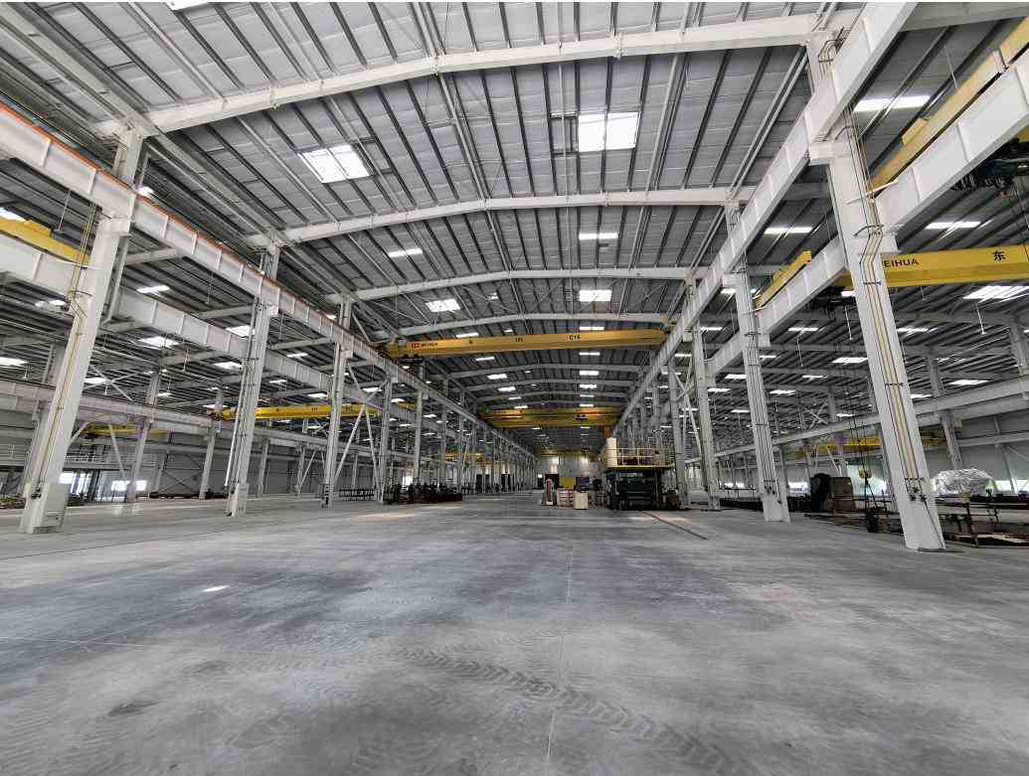

With the official unveiling of the company's new office building, we are able to glimpse the company's future development direction and vision. In this report, we will lead everyone into the company's new factory to explore the new construction and technological innovation of this modern factory.

一、Professional Purification and Polishing Room: A 'Green Barrier' to Protect Employee Health

In the new factory building, a professional polishing room is particularly eye-catching. This is equipped with an efficient air purification system. After the purification system is activated, a strong negative pressure quickly extracts dust while constantly replenishing fresh air. This design not only ensures fresh air in the polishing area, but also avoids the potential threat of dust to employee health.

二、New way of gas transportation: convenient, safe, and efficient "one-stop" service

In the traditional production mode, workers and masters need to frequently drag gas cylinders for operation, which not only increases the workload but also poses certain safety hazards. To address this issue, the new factory has introduced a centralized gas supply system. At the west gate of the company, two large gas cylinders stand tall, and the gas company injects gas directly into the cylinders through pipelines. These gases are then transported through pipelines densely distributed throughout the factory to every corner that requires gas. The masters can easily access the gas and start working next to the pillar. This new type of gas transportation method is not only convenient and efficient, but also greatly improves work safety.

三、Numerical Control Annealing Furnace: Intelligent Temperature Control, New Engine for Improving Production Efficiency

The new factory has introduced advanced CNC annealing furnaces, which will become a "new engine" for improving production efficiency with an intelligent temperature control system. Through computers, annealing furnaces can achieve automatic temperature adjustment and stable maintenance. Compared with traditional annealing furnaces, CNC annealing furnaces perform well in terms of work efficiency and control accuracy, providing effective support for the company to improve efficiency.

四、Gamma ray testing room: Strengthen quality testing to ensure that products are "consistent on the surface and inside"

In terms of product quality inspection, the new factory has taken an important step by adding a gamma ray inspection room, which also makes it possible to inspect thicker materials, thereby ensuring the reliability and stability of product quality. The application of gamma ray inspection room not only improves the accuracy of product quality testing, but also enhances the company's confidence in product quality.

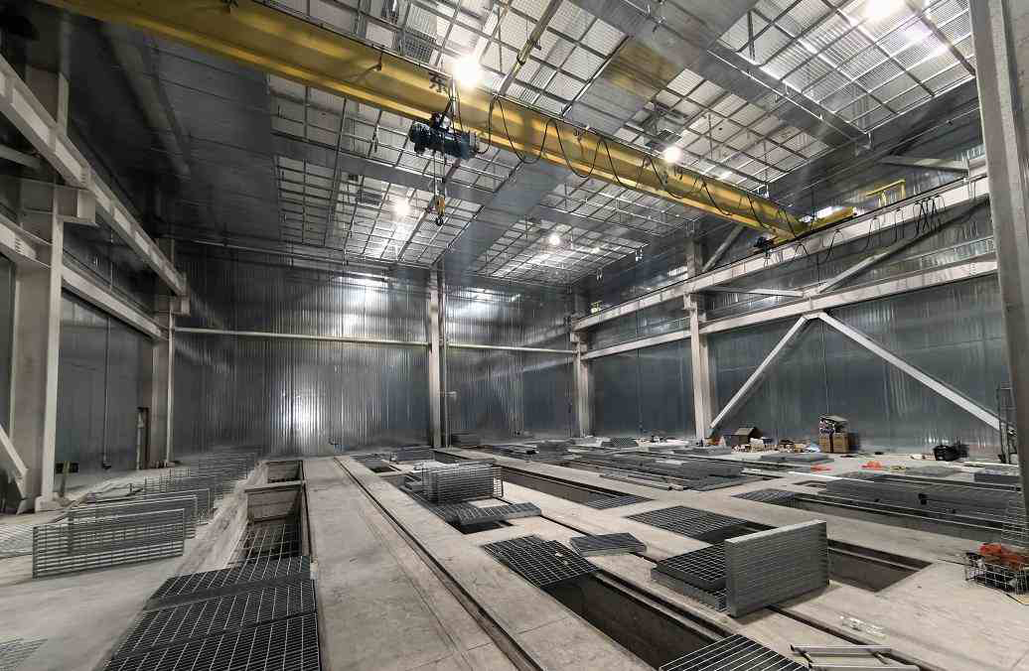

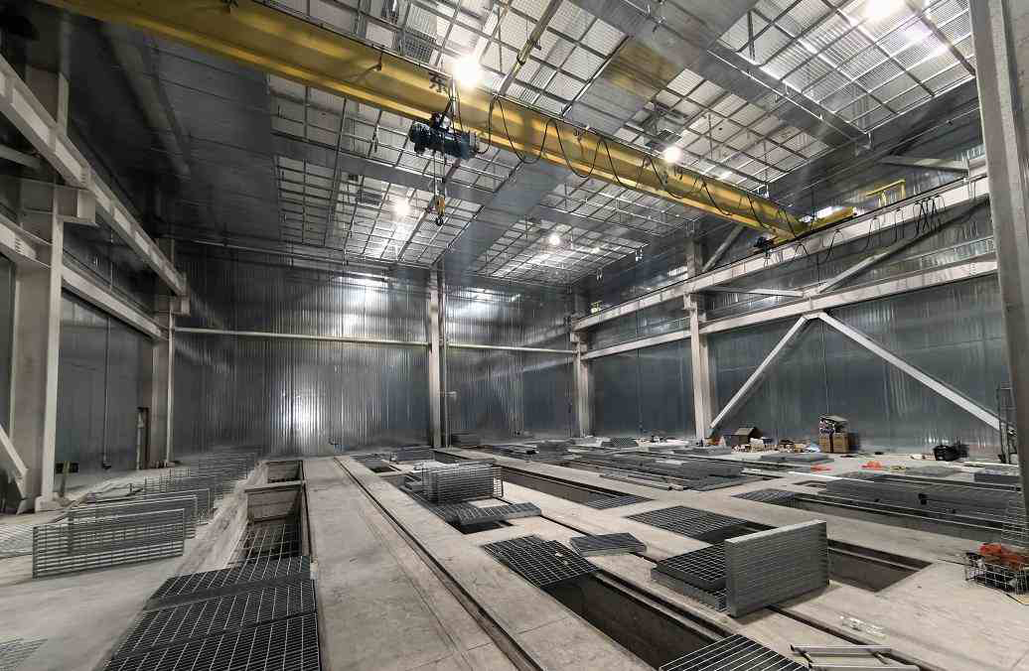

五、Professional sandblasting room: environmentally friendly and efficient, creating a "dust-free" working environment

The professional sandblasting room in the new factory has become a beautiful scenery with its unique design and efficient functions. The lower part of the sandblasting room adopts a steel grating design, combined with a conveyor belt to achieve automatic collection and recycling of sand materials. When the sand produced by sandblasting falls off the steel grating, it will be collected along the conveyor belt, processed, and reused. This design not only improves work efficiency, but also avoids the air pollution that may occur during traditional broom collection. At the same time, the negative pressure system in the sandblasting room also ensures a dust-free working environment, providing workers with a healthy and comfortable working environment.

六、Spray painting room and baking paint room: creating perfect coatings and showcasing the "beautiful" style of products

In order to meet the painting needs of different products, the new factory has specially set up two paint booths, one of which also has baking paint function. The paint booth adopts a mode of upward air supply and downward air extraction to ensure the air quality during painting operations. The extracted air is purified and discharged into the atmosphere, without causing pollution to the environment. At the same time, the walls of the paint booth are specially designed with good insulation performance, providing convenient conditions for baking paint operations and accelerating paint drying. Here, every product can receive perfect coating treatment, showcasing a beautiful style.

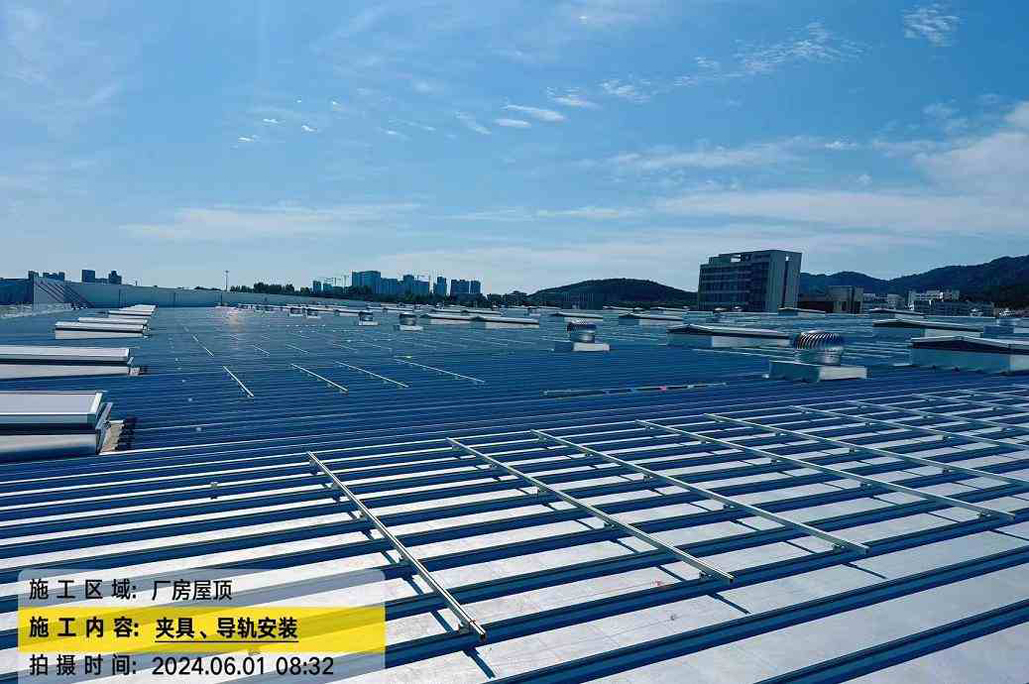

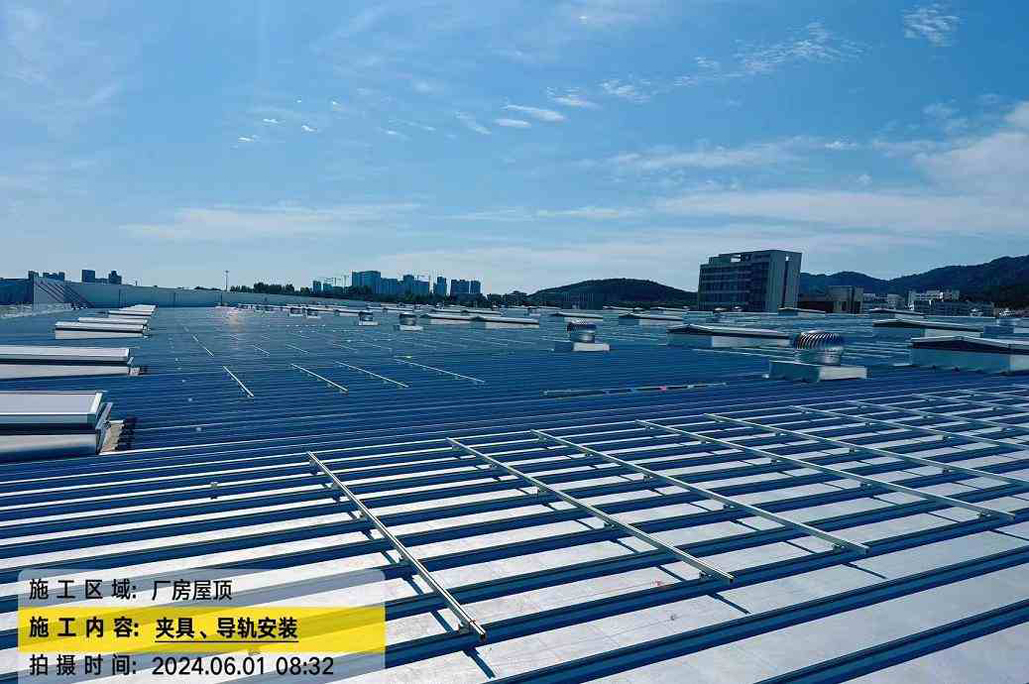

七、Green energy: photovoltaic panels help achieve self-sufficiency in electricity

Above the new factory building, the installation of photovoltaic panels has been put on the agenda. After installation, these photovoltaic panels will convert solar energy into electrical energy, providing the company with daily electricity needs. This measure not only reduces the company's operating costs, but also demonstrates the company's firm commitment to environmental protection. Through the application of photovoltaic panels, the new factory has achieved the use of green energy and contributed to sustainable development.

八、Rainwater utilization: Rainwater tanks store rainwater to help the company green

During the rainy season, the rainwater tank of the new company can store a large amount of rainwater as a watering source for the company's greenery. This design not only saves water resources, but also reduces the company's water costs. At the same time, the green plants irrigated by rainwater are more lush, adding a touch of vitality and energy to the factory.

At present, the construction work of the new factory is still in full swing. With the gradual introduction of various professional equipment, this modern factory will provide strong support for the company's future development. Let us look forward to the greater role this new factory will play in the future, injecting new vitality into the company's sustainable development.

EN

EN

EN

EN

2025-02-14

2025-02-14